Bearing Analysis

This page provides information about rolling bearing analysis and calculation methods. It is not about calculation software, MESYS Rolling Bearing Calculation Software would be one place to look for that.

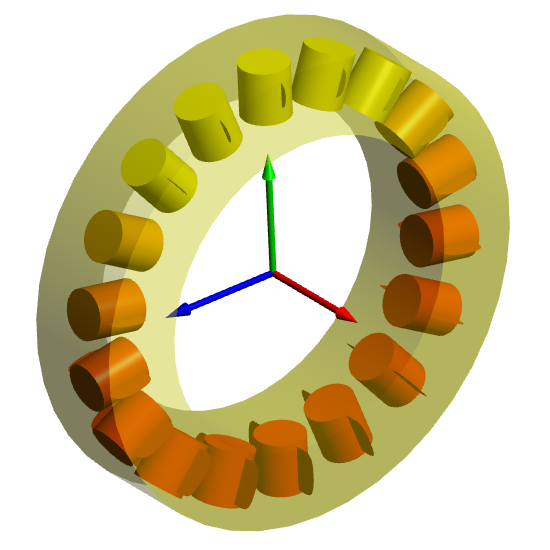

Rolling bearings are used to support shafts and still allow a rotation of the shaft. They have an inner ring, an outer ring and several rolling elements to separate the rings. Typical rolling elements are balls and cylindrical, tapered or sherical rollers. In many bearings a cage is used to separate the rolling elements, but for high load capacity also full complement bearing are used.

A bearing life calculation is usually either done according ISO 281 or ISO/TS 16281. The difference is that life according to ISO 281 does not take into account bearing clearance, tilting angle or moment load which is taken into account according to ISO/TS 16281.

Bearing clearance depends on the nominal clearance after manufacturing as shown in the bearing designation as C2, CN, C3, C4. This nominal clearance is decreased by fitting onto the shaft/housing with an interference fit. Further influence on the operating clearance have temperatures and centrifugal forces.

Bearing life according to ISO 281

The nominal bearing life can be calculated according to ISO 281. An equivalent load and the dynamic load capacity of the bearing are used for the calculation of bearing life.

Bearing life according ISO/TS 16281

Bearing life according ISO/TS 16281 requires the load distribution within the bearing and its load capacity. Therefore additional operations conditions like clearance or moment load can be considered.

Bearing load capacity according to ISO 281

The bearing load capacity is defined in ISO 281 and based of bearing geometry. Several factors are given in tables for standard parameters, if a different geometry is used additional information is provided in ISO 1281-1.

Modified bearing life

The modified bearing life takes into account lubricant viscosity and cleanliness and the ratio between load and fatigue limit of the bearing. A life modification factor for systems approach between 0.1 and 50 is then multiplied on nominal life.

Simple rolling bearings are either ball or roller bearings (there are also some combined types) and depending on the direction of the main load they support they are grouped into radial and axial bearings. An overview of the main bearing types is shown on the next pages.

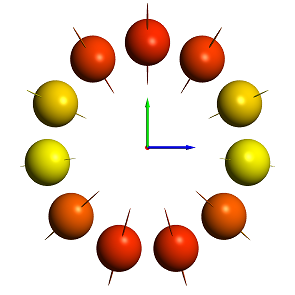

Radial ball bearings

Radial ball bearings use balls as rolling elements and have a contact angle less equal 45°. Most important types are radial deep groove ball bearings and angular contact ball bearings.

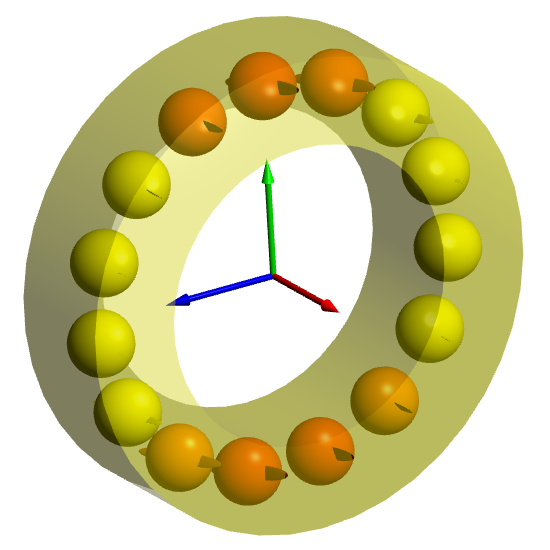

Radial roller bearings

Radial roller bearing use either cylindrical, tapered or spherical rollers and have a contatc angle less equal 45°. Most important types are radial cylindrical roller bearings, taper roller bearings and double row spherical roller bearings.

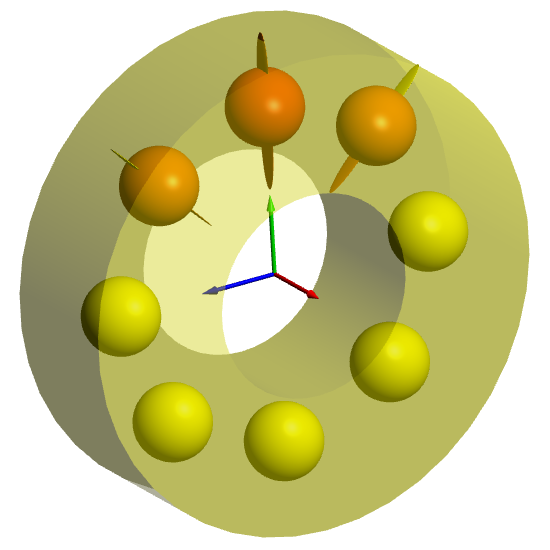

Axial ball bearings

Axial ball bearings have an contact angle larger 45°. Most important types are axial deep groove ball bearings or axial angular contact ball bearings.

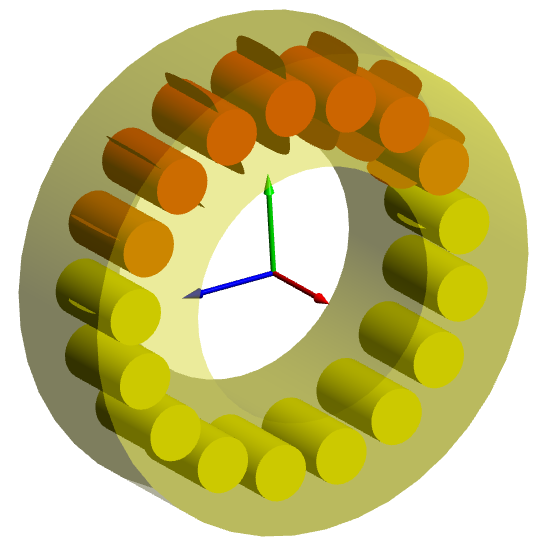

Axial roller bearings

Axial roller bearings use either cylindrical, tapered or spherical rollers and have an contact angle larger 45°. Axial cylindrical roller bearings or axial spherical roller bearings are the most common ones.