Axial ball bearings

Axial ball bearings have an contact angle larger 45°. Most important types are axial deep groove ball bearings or axial angular contact ball bearings.

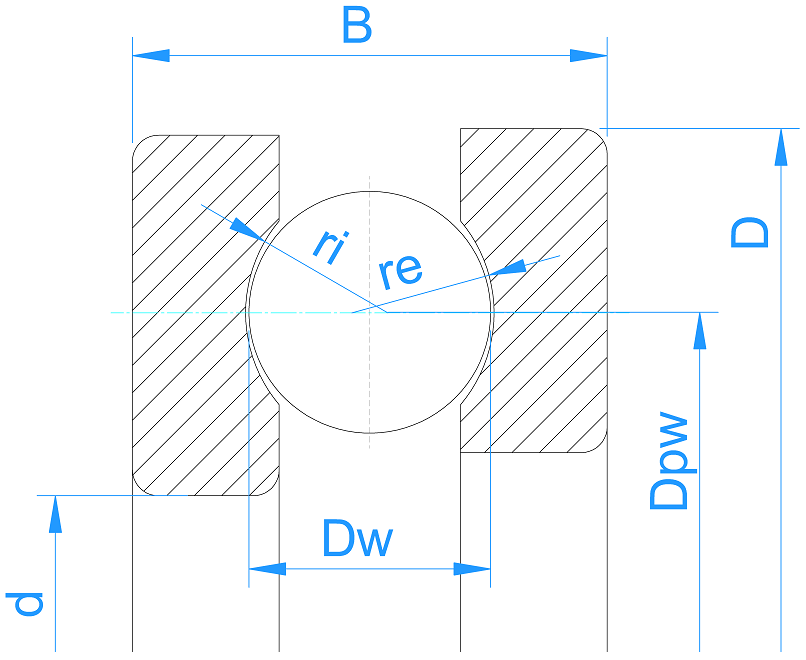

Deep groove ball bearing

Axial deep groove ball bearings are composed of shaft locating washers, housing locating washers and ball and cage assemblies. All the parts can be fitted and removed separately as the bearings are not self retaining. Axial deep groove ball bearings are available in single and double direction designs and are able to support high axial forces but cannot tolerate radial loads.

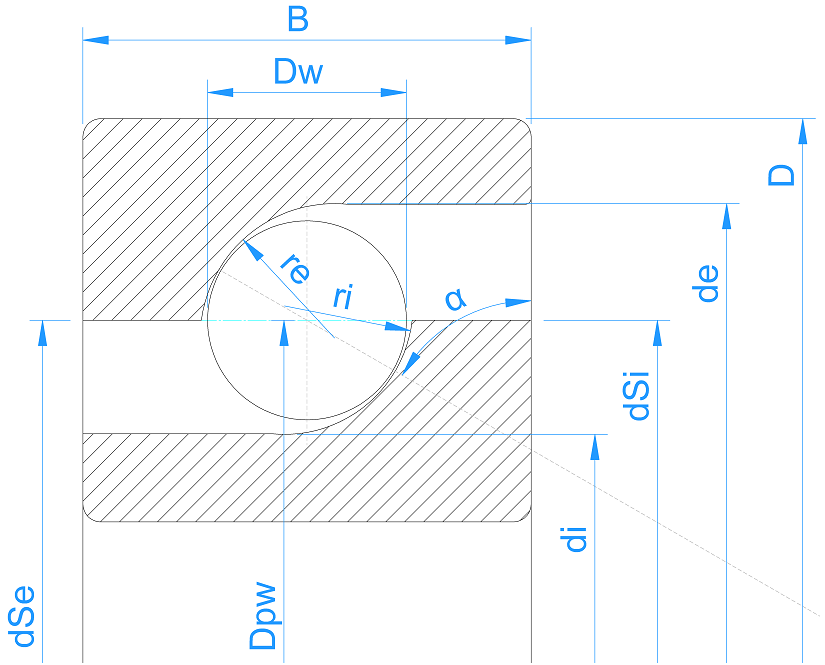

Angular contact ball bearing

The working principle of axial angular contact bearings is the same as the radial angular contact ball bearing and the most striking difference between the two types lays on their contact angle. Standard axial angular contact bearings have a contact angle of 60°, while in the radial design are 15°, 25° or 40°. This feature enables the axial design, for obvious reasons, to accommodate heavier axial loads.

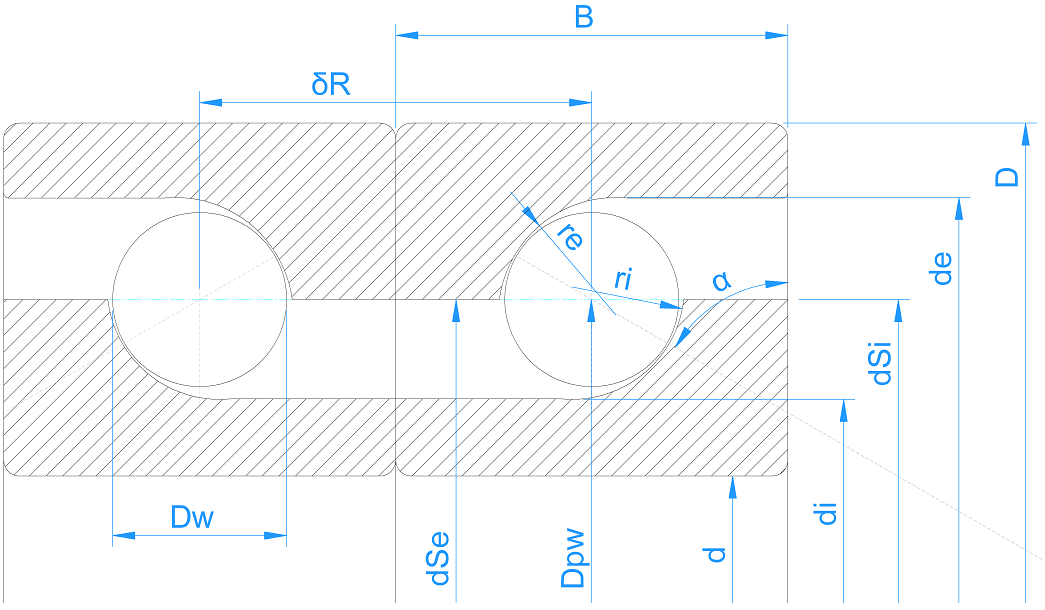

Angular contact ball bearing (double row)

Axial angular contact ball bearings are usually available in double row or triple row ready-to-fit self-retaining units. These bearings are primarily used for the bearing arrangements of screw drives and constitute an economical solution with regard to simple adjacent constructions and fitting costs. They deliver an extremely high dynamic and static load carrying capacity in the axial direction are suitable for high speeds in terms of its diameter. The bearing rings are matched to each other such that a defined preload is achieved once the rings are clamped together through a precision locknut.

Four point ball bearing

These bearing are equivalent to the radial four-point angular contact ball bearing but it has contact angles bigger than 45° and therefore is calculated as an axial bearing type. This modification enables this bearing to accommodate higher axial loads at the expense of even lower radial load capacities.

.png)