Axial roller bearings

Axial roller bearings use either cylindrical, tapered or spherical rollers and have an contact angle larger 45°. Axial cylindrical roller bearings or axial spherical roller bearings are the most common ones.

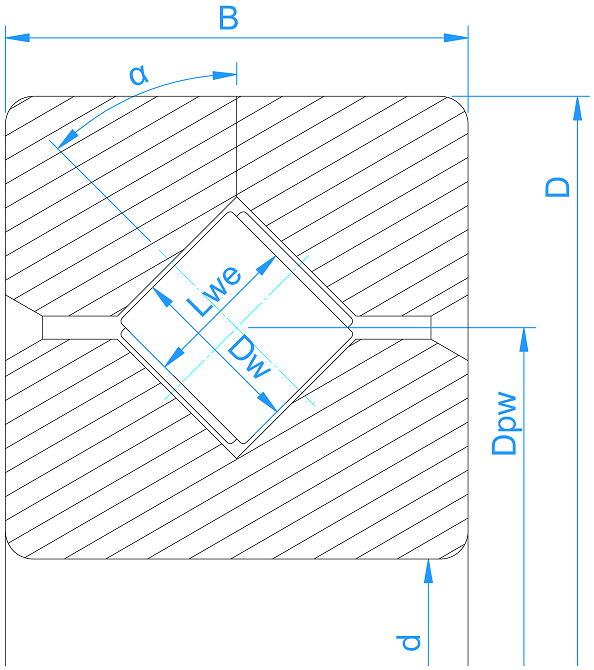

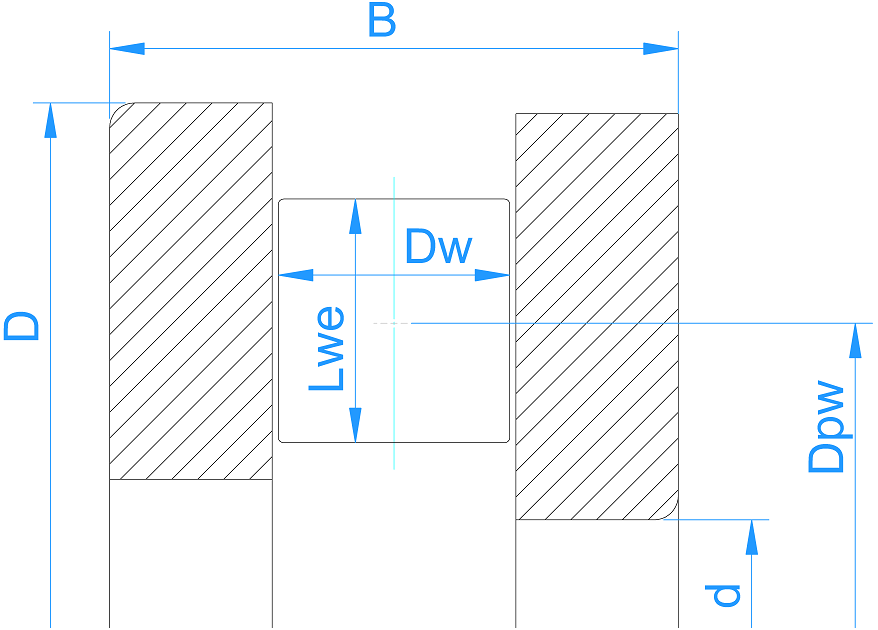

Cylindrical roller thrust bearing

Cylindrical roller thrust bearings are basically designed to accommodate heavy axial loads and shock loads and are therefore unsuitable to support moment and radial loads. Cylindrical roller thrust bearings have a very high stiffness, require little axial space and permit relatively high speeds. The bearing assembly can be dismantled and the parts of the bearings can be fitted separately. Cylindrical roller thrust bearings can be manufactured with one or two rows of rollers and are mainly used in applications where the load carrying capacity of thrust ball bearings does not suffice. Depending on the design, can accommodate axial loads in both directions. Some field of application are, for example, gearboxes, calenders, engines in marine applications and rudder engines, lifting gear, construction machinery and rolling mills.

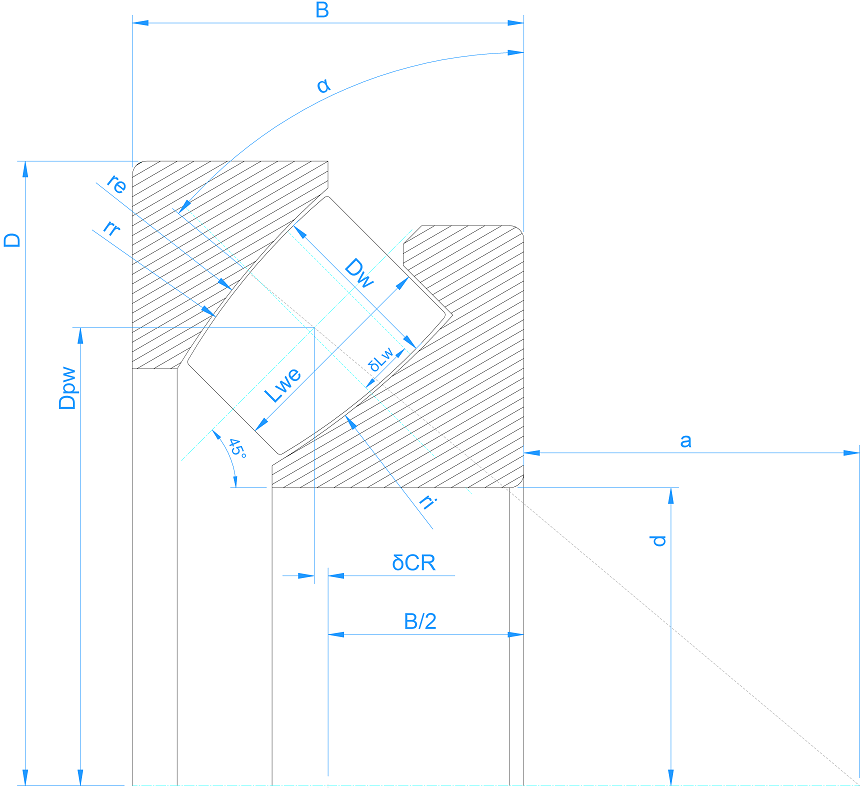

Spherical roller thrust bearing

Spherical thrust roller bearings contain a large number of asymmetrical convex rollers. These bearings have a self-aligning capability in operation and are insensitive to mounting errors or shaft deflection. The rollers feature an optimum conformity with specially designed raceways thus optimizing the load distribution along the roller length. The load is transmitted between the raceways at certain angle to the bearing axis. In this way, they can accommodate relatively high speeds, very heavy axial loads in one direction and heavy radial loads.

Crossed roller bearing

Crossed roller bearings are designed for precision applications as they are capable of supporting bearing loads in every direction with high rotation accuracy while conserving space and volume. The outer ring is split and is held together by three retaining rings. Since the cylindrical rollers are orthogonally arranged with respect to each other, these bearings can accommodate axial forces from both directions as well as radial forces, tilting moment loads and any combination of loads with a single bearing position. This feature allows other designs that require two bearing positions to be reduced to a single bearing position. Generally, crossed roller bearings bearings are very stiff and are supplied with normal clearance, little clearance or preload. They are optimal for the table bearing of machine tools, including vertical boring and grinding machines, and widely used in automatic control, robotics, medical and inspection devices.